Copyright: Vogel Communications Group

https://pharma-engineering.glatt.com/wp-content/uploads/2024/08/Glatt_FA_129_Cleanroom-Design.-Doors-glazing-walls-and-fixtures_en_process-worldwide.com_2024-06_2s.jpg

1069

1604

Mona Berger

https://pharma-engineering.glatt.com/wp-content/uploads/2021/11/glatt-logo-web-160.png

Mona Berger2024-08-22 15:14:242024-09-23 14:21:37Cleanroom design. Doors, glazing, walls, fixtures

Copyright: Vogel Communications Group

https://pharma-engineering.glatt.com/wp-content/uploads/2024/08/Glatt_FA_129_Cleanroom-Design.-Doors-glazing-walls-and-fixtures_en_process-worldwide.com_2024-06_2s.jpg

1069

1604

Mona Berger

https://pharma-engineering.glatt.com/wp-content/uploads/2021/11/glatt-logo-web-160.png

Mona Berger2024-08-22 15:14:242024-09-23 14:21:37Cleanroom design. Doors, glazing, walls, fixturesMore than 30 years of engineering expertise and experience

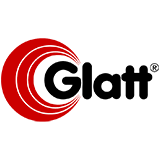

For more than 30 years, Glatt Ingenieurtechnik GmbH has been planning and realising international projects from the enlargement or modernization of existing production facilities to the construction of whole new factories. Glatt is a leading plant engineering partner in the pharmaceutical, biotechnology, chemicals, fine chemicals, food and pet food industries.

Glatt Ingenieurtechnik is a company of the internationally active Glatt Group. Our planning engineers, process experts, project managers and many other specialists work in the Glatt competence areas ‘Process & Plant Engineering Pharma+Biotech‘ and ‘Process Technology Food, Feed & Fine Chemicals‘.

The tasks entrusted to our Process & Plant Engineering Pharma+Biotech teams range from the expansion or modernization of existing production facilities to the construction of entire new plants for the manufacture of solid, semi-solid, liquid and sterile dosage forms. Our projects focus on the development and optimization of processes for the manufacture of pharmaceutical and biotechnological products such as tablets, coated tablets, capsules, injection and infusion solutions, drops and juices, ointments, vaccines, insulin, blood plasma products, biosimilars, active pharmaceutical ingredients – chemical API and biotechnological API. As required, we support our customers as planners in individual project phases or as general planners or general contractors. We integrate customer technologies or pioneering Glatt technologies into our planning using modern modular planning approaches and applying integreted automation and robotic systems.

We combine professional engineering with sound technical know-how derived from patented process technologies, such as Glatt powder synthesis and fluidized and spouted bed methods for granulation and coating processes. As an integral part of the international Glatt Group, Glatt Ingenieurtechnik can draw on a global network of some 3000 employees. Numerous agencies exist worldwide as contacts for the full range of goods and services.

Our mission

For us, everything revolves around professional engineering with reliable know-how:

We transfer your processes into GMP compliant solutions and integrate Glatt technology on request.

Our sites

The primary location of Glatt Ingenieurtechnik with its technology center is in Weimar, Germany. Further branches and affiliated companies are located in Wiesbaden, Cologne, Dresden, Switzerland, Russia, India and the USA.

Glatt Ingenieurtechnik is integrated into the international Glatt Group and has a global network of around 3,000 employees. Numerous representatives are available worldwide as contacts for the full range of services.

Our values

Innovative

We are driven by innovation and a passion for research.

Technological

With technology in focus, we adapt all other functions.

Functional

We do not use architectural models. Function determines form, from the inside out.

High quality

Customized solutions. Highest quality standards for our service and your product.

Flexible

Short decision-making processes.

Lean management.

Flexible thinking models.

Sustainable

Green technologies. Design of resource-efficient plants. Certified environmental management.

Qualified

Qualified process and planning engineers with extensive experience.

Regional

We are represented worldwide.

There is always a contact person available in your region.

International

Borderless: We realize projects on all continents.

Connected

In research projects. With scientific institutions and industry partners.

Our development

Since we were founded in 1991, Glatt Ingenieurtechnik has developed into a globally recognized and reliable system provider of integrated process solutions. We have developed a comprehensive portfolio of particle technologies for the bulk solids processing industries in the food, feed and chemical sectors.

Our certifications

Modern process technology for the production of high-quality powders, granules and pellets for satisfied customers – that is our claim. We ensure this with monitored quality control.

Our company is therefore certified according to:

- ISO 9001 and 14001 standards

- FSSC 22000 (Food Safety System Certification)

- EcoVadis rating for sustainable action

You can download the documents here.

Latest News round about Glatt Ingenieurtechnik

Copyright: Vogel Communications Group

https://pharma-engineering.glatt.com/wp-content/uploads/2024/08/Glatt_FA_129_Cleanroom-Design.-Doors-glazing-walls-and-fixtures_en_process-worldwide.com_2024-06_2s.jpg

1069

1604

Mona Berger

https://pharma-engineering.glatt.com/wp-content/uploads/2021/11/glatt-logo-web-160.png

Mona Berger2024-08-22 15:14:242024-09-23 14:21:37Cleanroom design. Doors, glazing, walls, fixtures

Copyright: Vogel Communications Group

https://pharma-engineering.glatt.com/wp-content/uploads/2024/08/Glatt_FA_129_Cleanroom-Design.-Doors-glazing-walls-and-fixtures_en_process-worldwide.com_2024-06_2s.jpg

1069

1604

Mona Berger

https://pharma-engineering.glatt.com/wp-content/uploads/2021/11/glatt-logo-web-160.png

Mona Berger2024-08-22 15:14:242024-09-23 14:21:37Cleanroom design. Doors, glazing, walls, fixtures

Modular ATMP Production. ACHEMA 2024

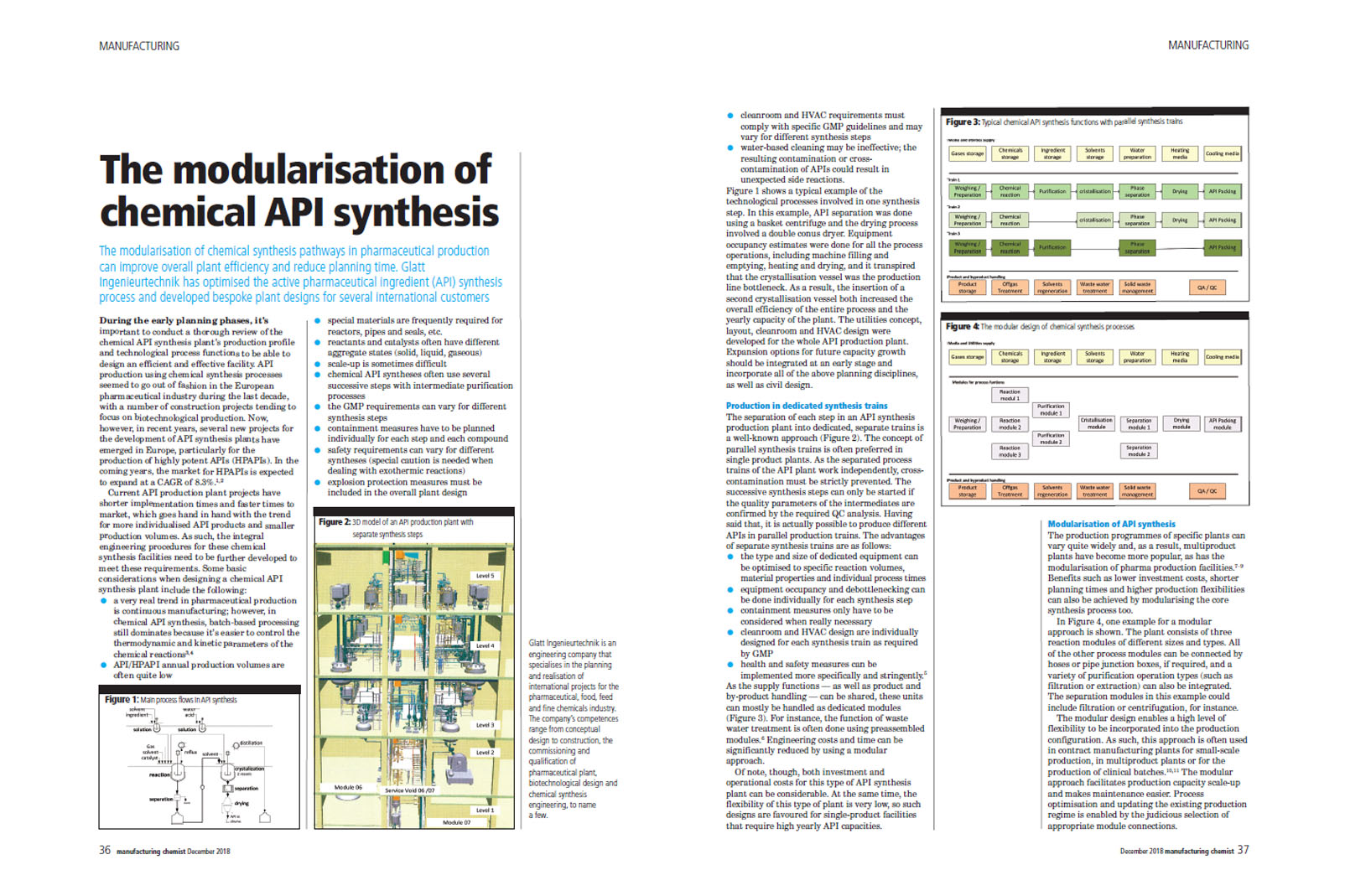

Modularisation of chemical API synthesis. ACHEMA 2024

Glatt Engineering with Robotics at ACHEMA 2024

Glatt presentation on MODULAR PLANNING at Lounges 2024

Copyright: Wiley-VCH Verlag GmbH & Co. KGaA

Copyright: Wiley-VCH Verlag GmbH & Co. KGaABioCampus MultiPilot plant as a catalyst for industrial biotechnology

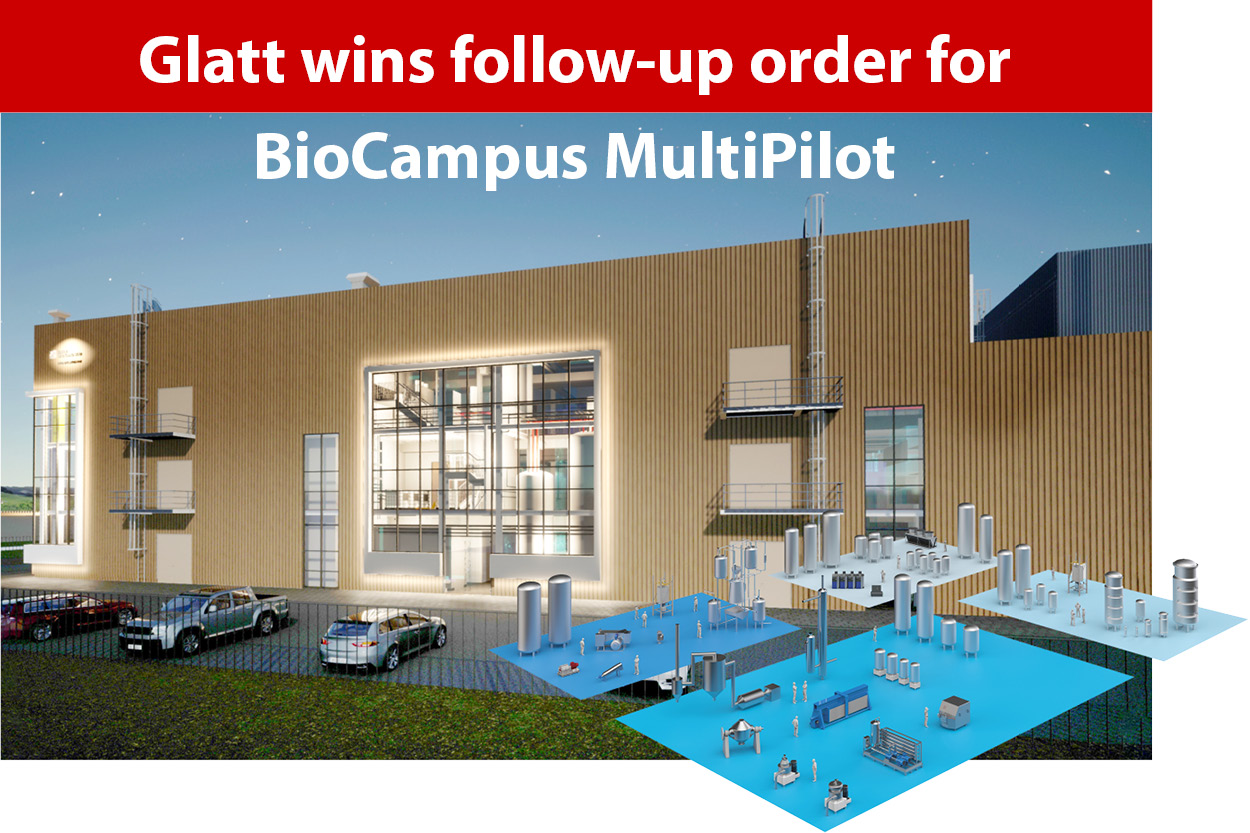

Copyright: ZVH Straubing

Copyright: ZVH StraubingGlatt wins follow-up order for BioCampus MultiPilot

Copyright: HPCi Media Limited

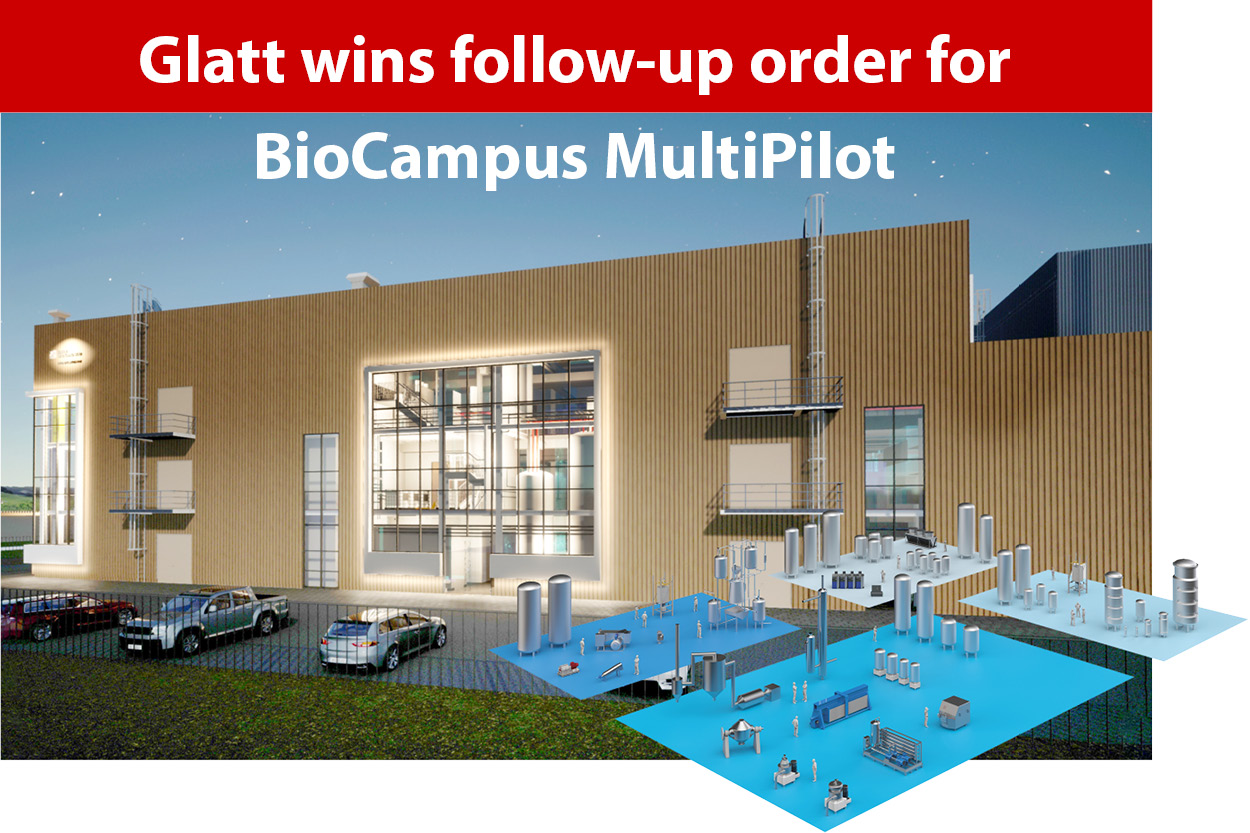

Copyright: HPCi Media LimitedThe design and modularisation of API synthesis plants

Copyright: Wiley-VCH Verlag GmbH & Co. KGaA

Copyright: Wiley-VCH Verlag GmbH & Co. KGaACleanroom engineering. From the idea to production

Copyright: Stephan Kurz, Bayer AG

Copyright: Stephan Kurz, Bayer AG ISPE RAYA 2023 Award. SOLIDA 1-Bayer-Leverkusen-Germany

Copyright: Inter-Euro Medien

Copyright: Inter-Euro MedienExploring new ways to produce cosmetic pigments – Interview with Merck and Glatt about the cooperation and the project

Jens Lehnert, Funkemedien

Jens Lehnert, FunkemedienManaging Director Reinhard Böber leaves Glatt Ingenieurtechnik GmbH to retire

Copyright: Jens Lehnert, Thüringer Landeszeitung

Copyright: Jens Lehnert, Thüringer LandeszeitungGlatt and Merck start up novel plant for the production of effect pigments

Copyright: Jens Lehnert

Copyright: Jens LehnertGlatt joins forces with Merck for cosmetic pigment production – Festive inauguration of the Dryflux facility

Copyright: Vogel Communications Group

Copyright: Vogel Communications GroupCleanroom design. Ceilings and installations.

Copyright: LEG Thüringen

Copyright: LEG ThüringenGlatt Ingenieurtechnik honored as a “Hidden Champion” made in Thuringia

Copyright: Glatt

Copyright: GlattWith short time-to-market from process development directly to contract manufacturing

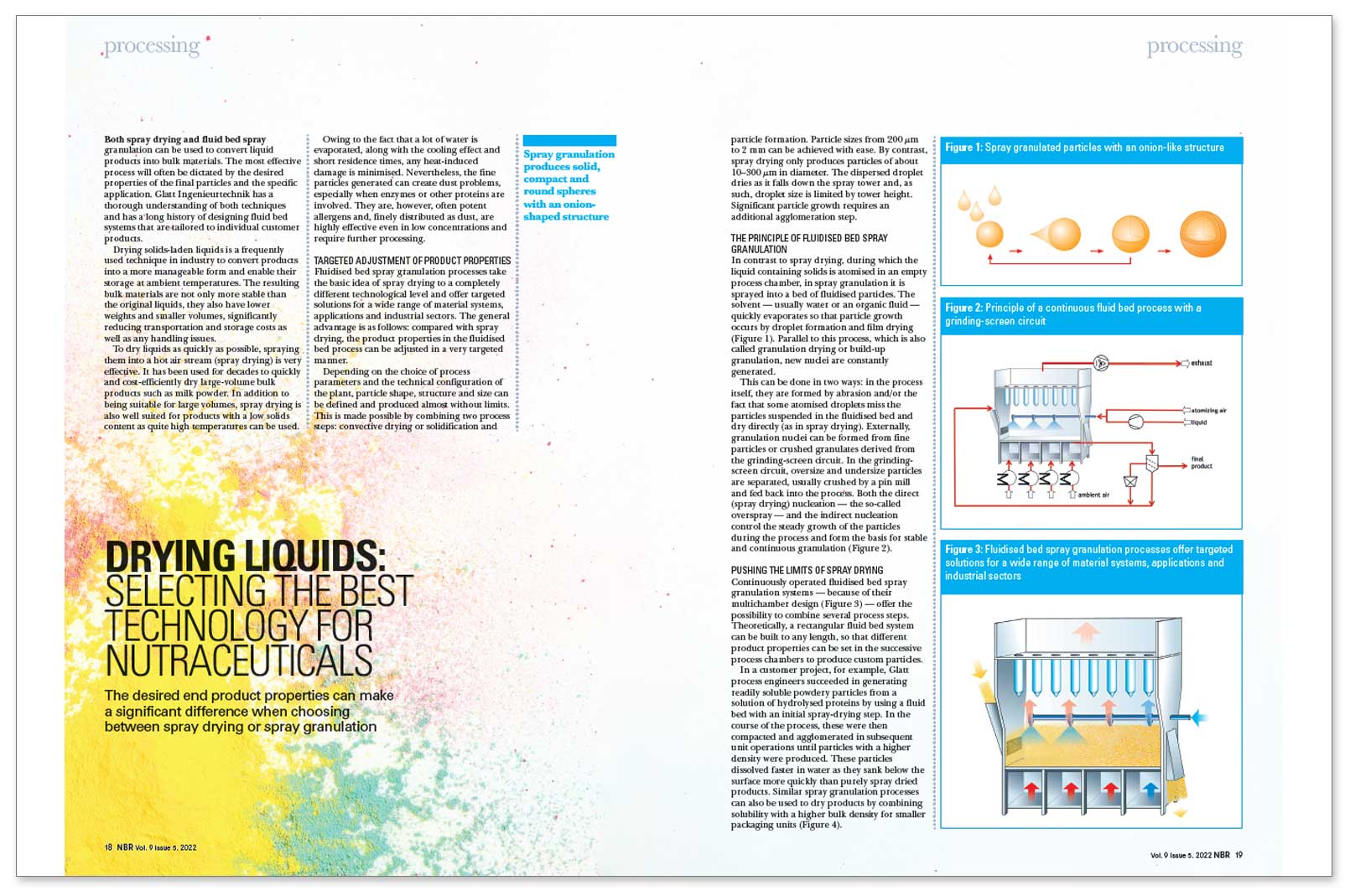

Copyright: HPCi Media Limited

Copyright: HPCi Media LimitedDrying liquids – Selecting the best technology for nutraceuticals

Copyright: Thomas Müller

Copyright: Thomas MüllerBodo Ramelow, Minister President of the Free State of Thuringia, visits Glatt Ingenieurtechnik

Copyright: Glatt

Copyright: GlattGlatt and IE Group commissioned to plan the world’s first integrated precision and mycelium fermentation protein plant

Copyright: Glatt

Copyright: GlattGlatt Ingenieurtechnik GmbH in Weimar puts 100 kWp photovoltaic sytsem into operation

Glatt selected for Engineering Project for new GMP Biorefinery by NSTDA in Thailand

Copyright: Bayer AG

Copyright: Bayer AGTopping-out ceremony for SOLIDA 1 at Bayer in Leverkusen, Germany

Copyright: Glatt

Copyright: GlattGlatt expands engineering capacity in Cologne, Germany

Copyright: ZVH Straubing

Copyright: ZVH StraubingGlatt commissioned to plan new BioCampus

Glatt to inaugurate vaccine production in Ghana

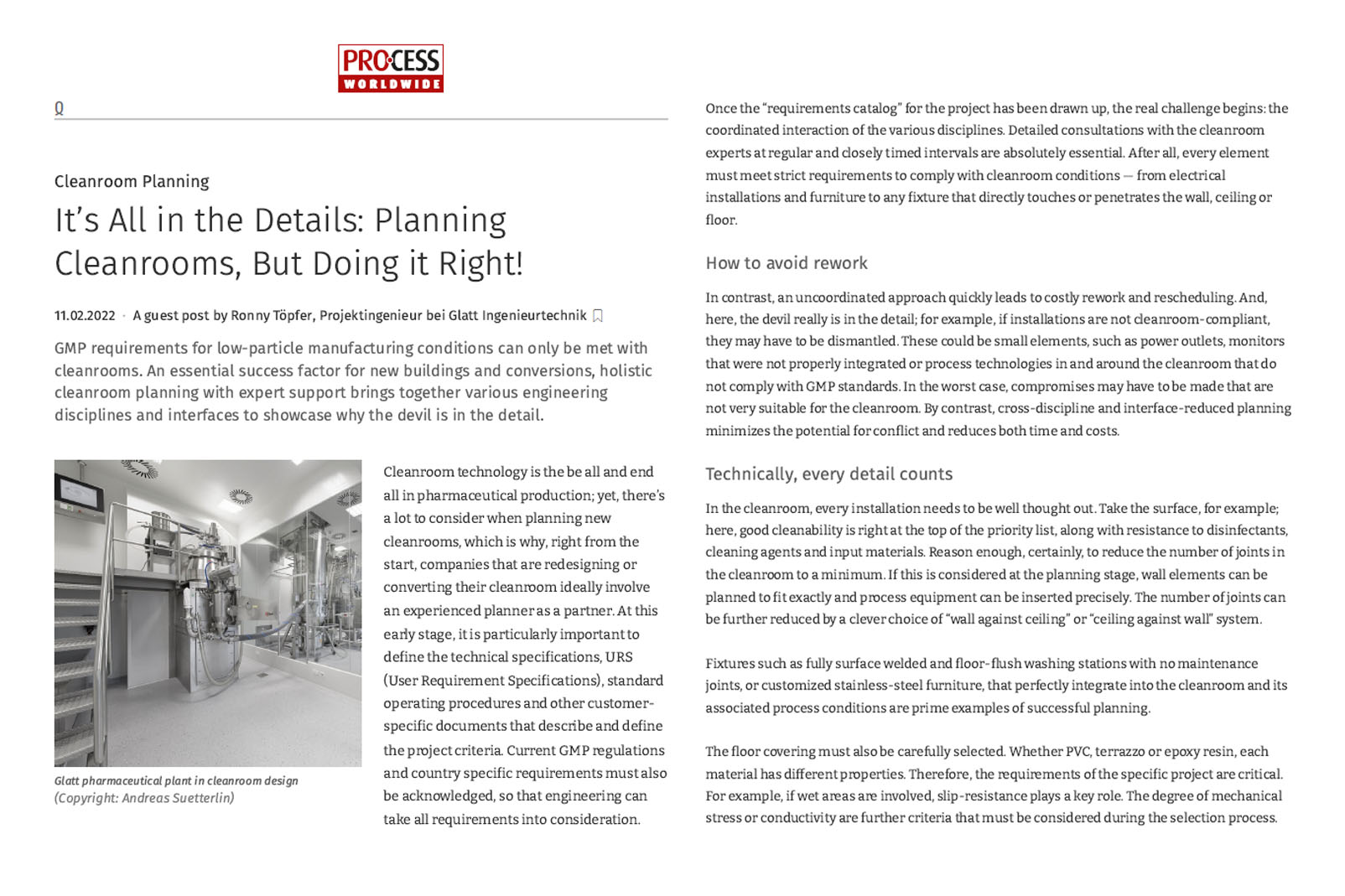

Copyright: Vogel Communications Group

Copyright: Vogel Communications GroupAvoiding mistakes in cleanroom construction

Maintenance-free cleanroom washing area

Copyright: Hüthig GmbH

Copyright: Hüthig GmbHOutsourcing of the production – Trust in competent partners

Copyright: SIGWERB GmbH

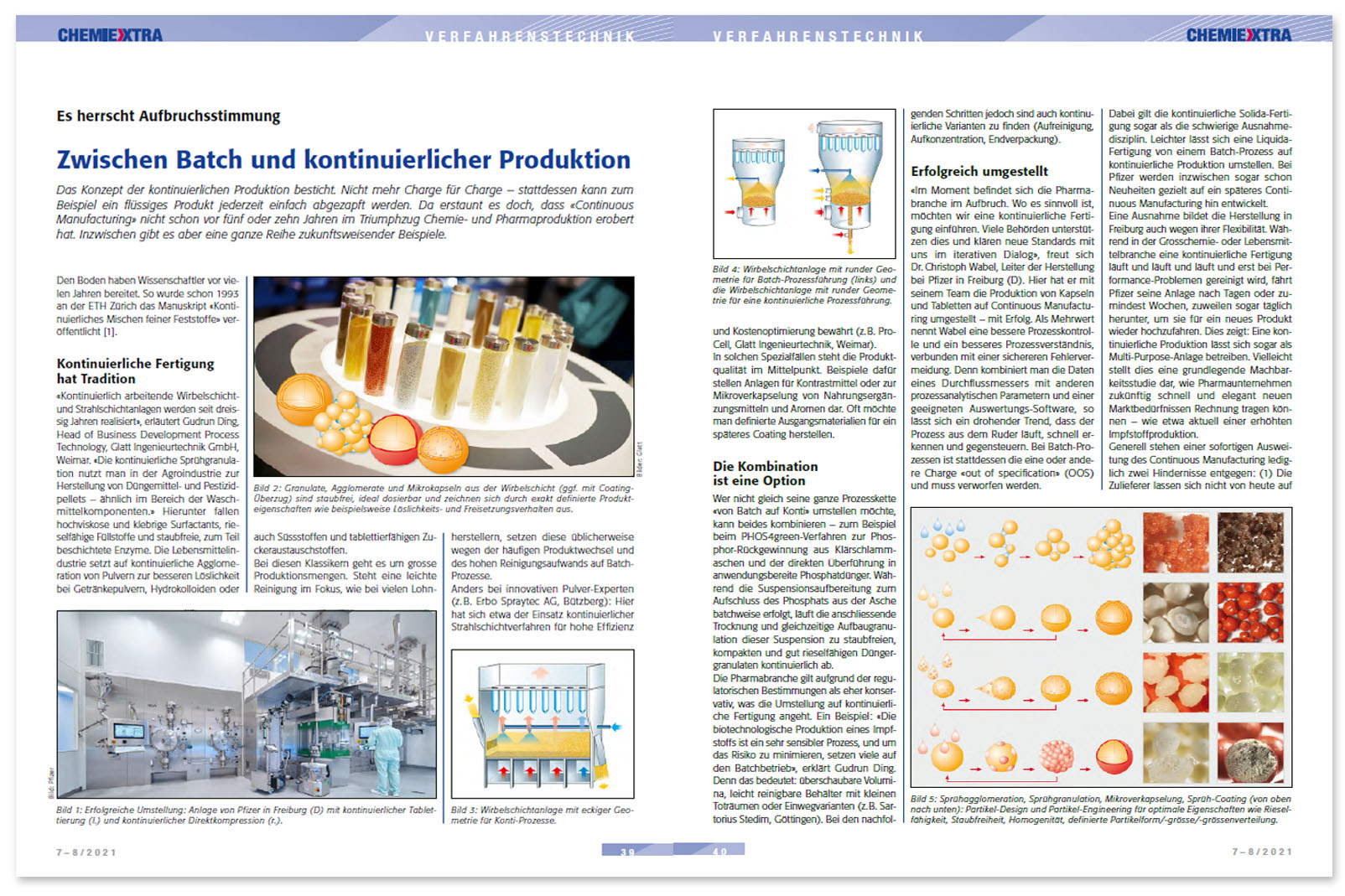

Copyright: SIGWERB GmbHA spirit of optimism between batch and continuous production

Copyright: Hüthig GmbH

Copyright: Hüthig GmbHImplementing containment requirements in solids manufacturing

Copyright: HPCi Media Limited

Copyright: HPCi Media LimitedHow to Tame Recalcitrant Ingredients with Technological Processes

Copyright: Glatt

Copyright: GlattNew fluid bed options for solvent-based processes and products requiring Kosher and Halal conditions

Copyright: publish-industry Verlag GmbH

Copyright: publish-industry Verlag GmbHFluid bed systems: continuous, batch or a hybrid?

Glatt Ingenieurtechnik honored as an outstanding company with the East German Business Forum Award

Copyright: Glatt

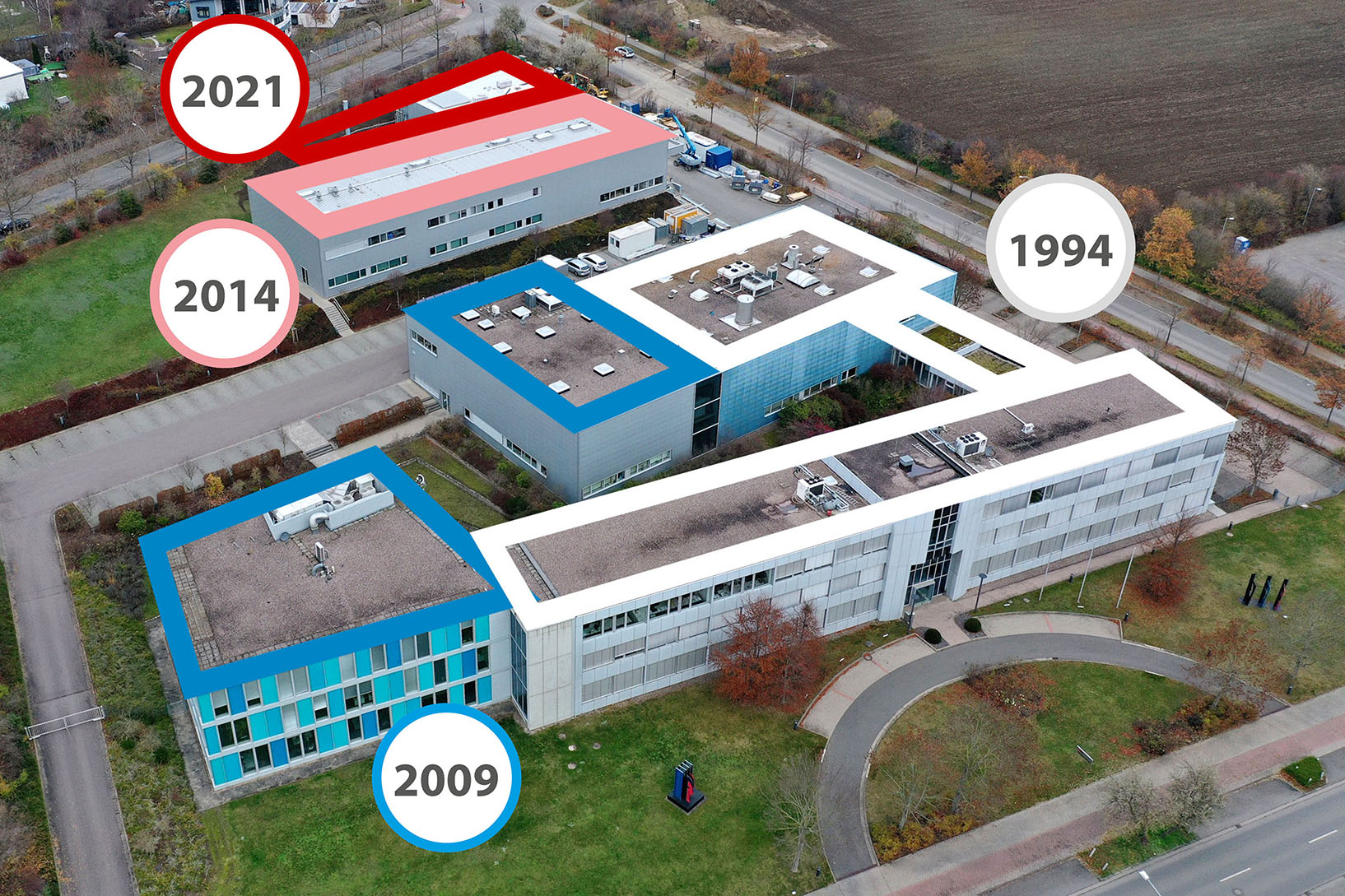

Copyright: GlattGlatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

Copyright: Hüthig GmbH

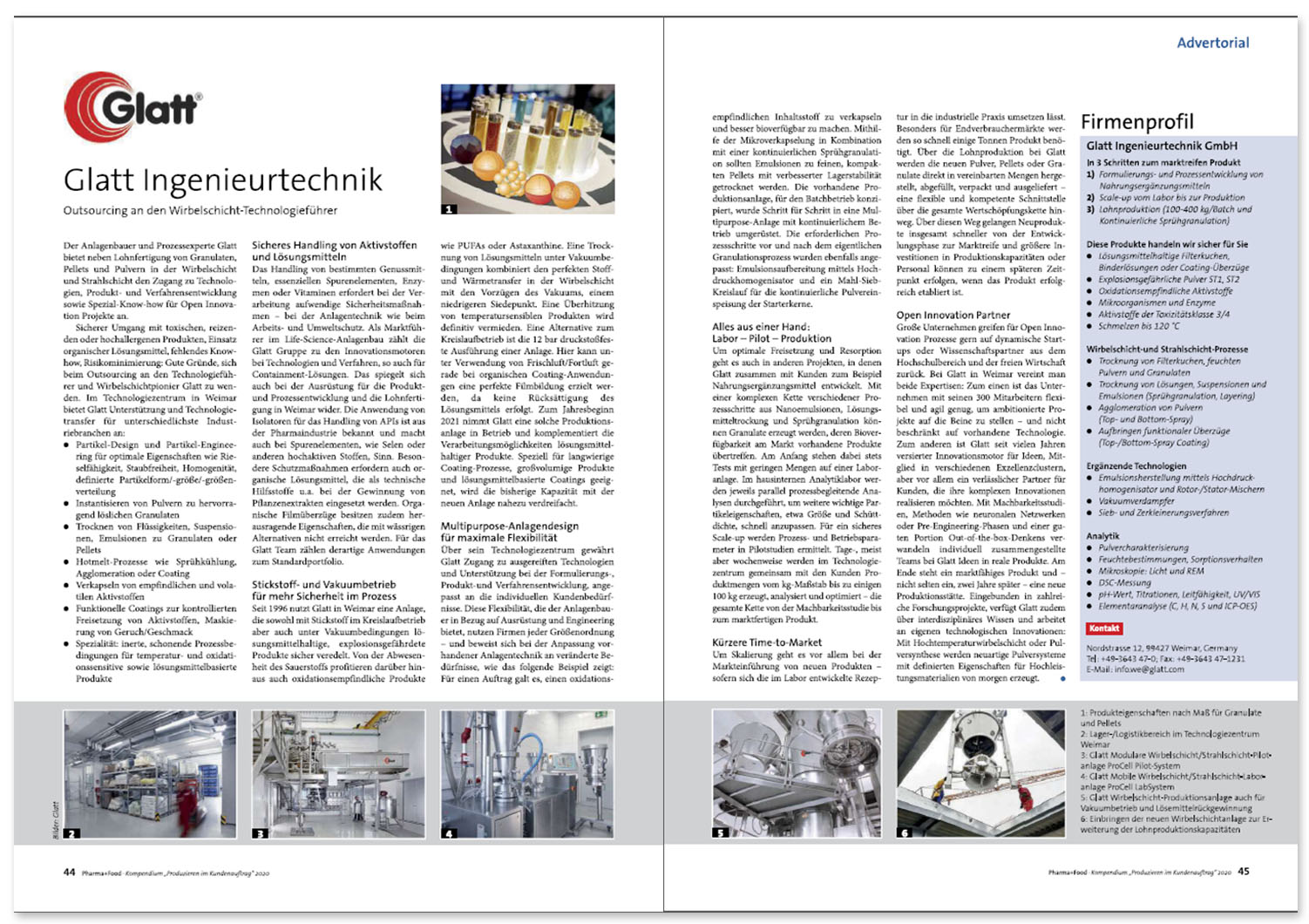

Copyright: Hüthig GmbHOutsourcing to the fluid bed technology leader

Copyright: Fachwelt Verlag

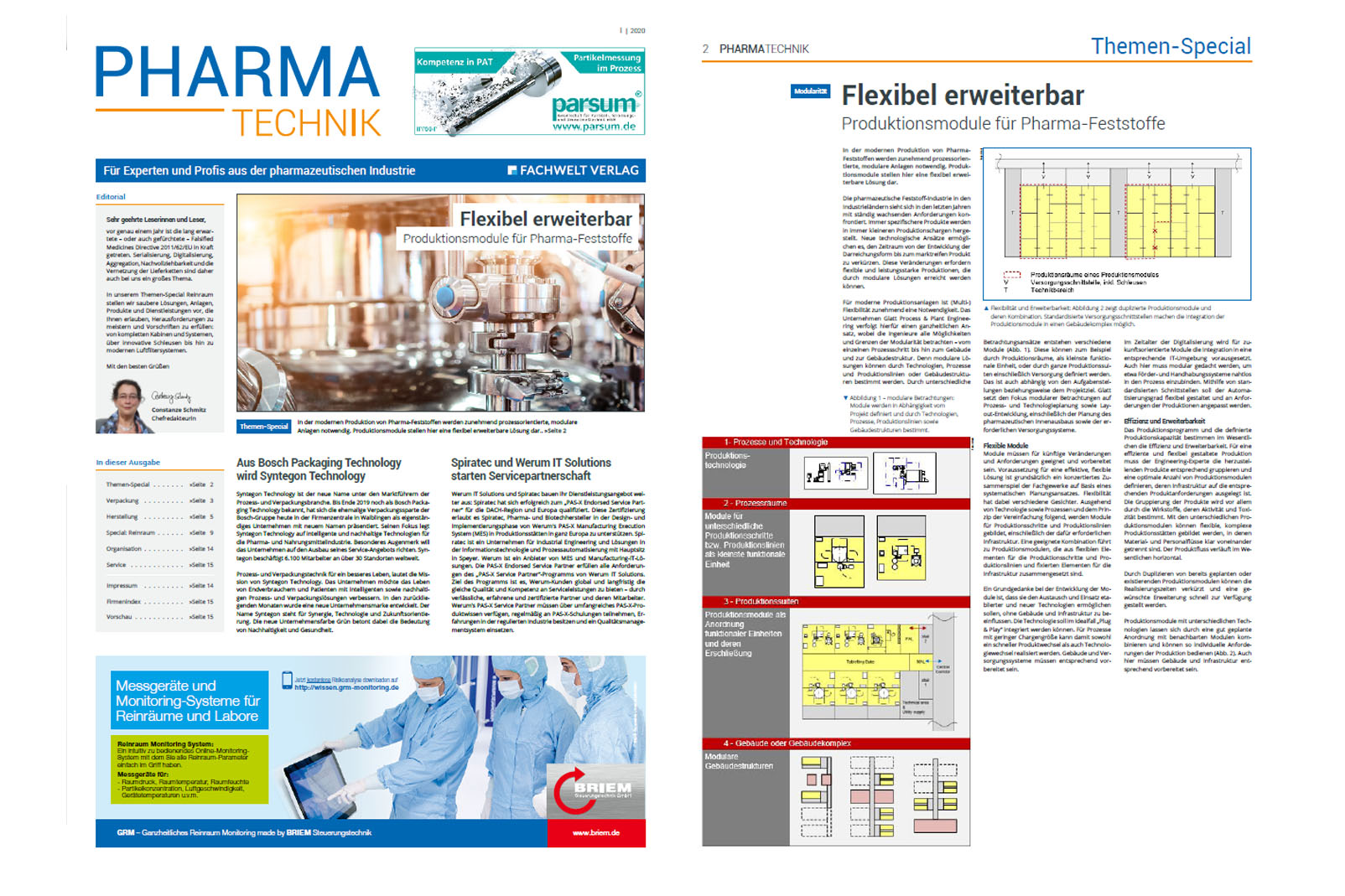

Copyright: Fachwelt VerlagFlexible production modules for pharmaceutical solids

Copyright: Hüthig GmbH

Copyright: Hüthig GmbHNew Challenges for Material Handling in Pharmaceutical Production

Glatt Ingenieurtechnik GmbH is one of the 150 most innovative companies in Eastern Germany

Modularisation of chemical API synthesis

Copyright: publish-industry Verlag GmbH

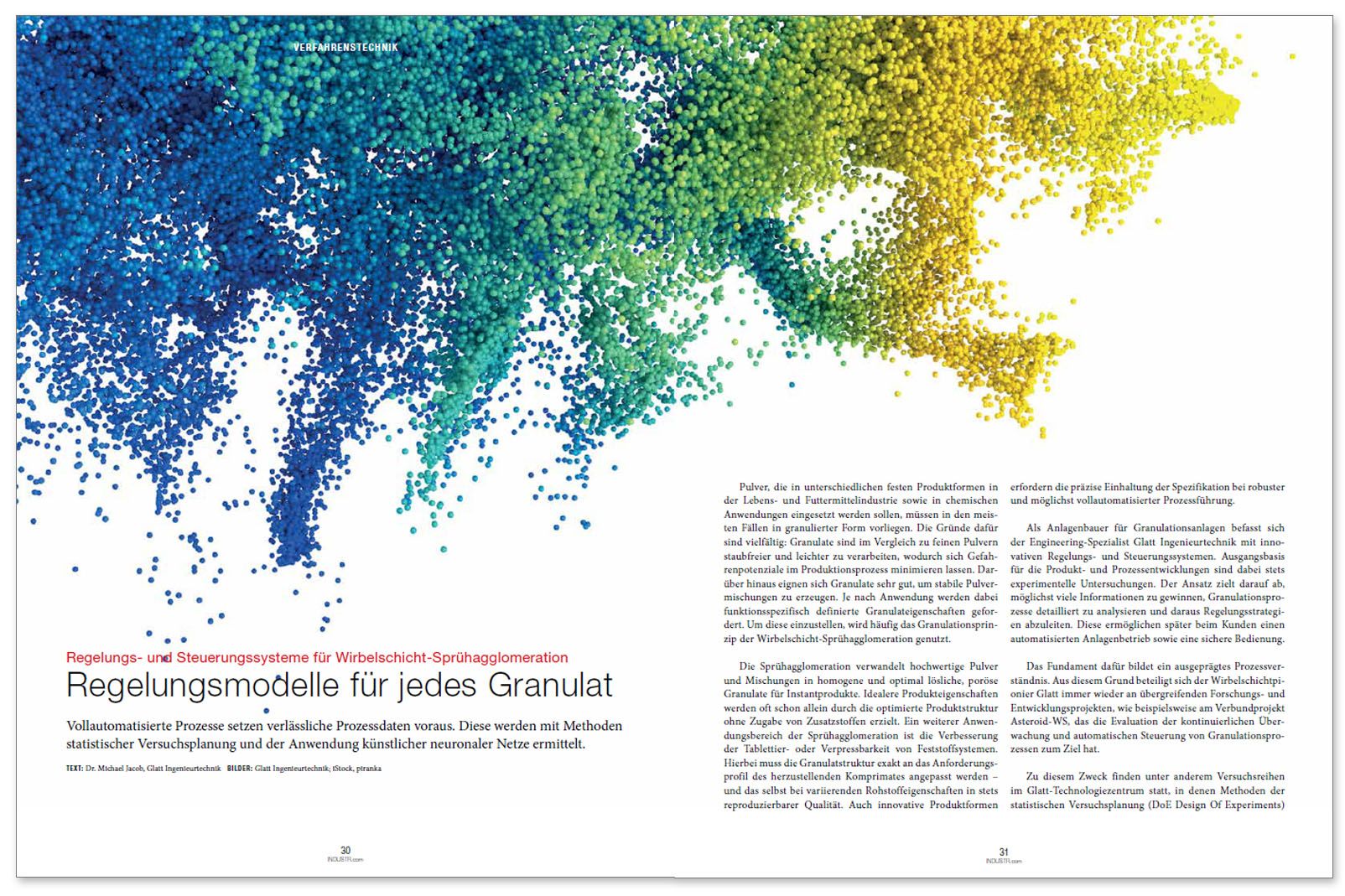

Copyright: publish-industry Verlag GmbHRegulation and control systems for fluid bed spray agglomeration

Copyright: Glatt

Copyright: GlattModular planning for flexibility in pharmaceutical production

Copyright: Vogel Communications Group

Copyright: Vogel Communications GroupMoving the production of biopharmaceuticals to Asia

Copyright: Glatt

Copyright: GlattContainment solutions only cost-effective when adapted

Copyright: Vogel Communications Group

Copyright: Vogel Communications GroupSuccess Factor Containment – Safe contract manufacturing with zero contamination

Glatt Ingenieurtechnik continues to grow in Dresden

Strengthening of pharmaceutical engineering capacities

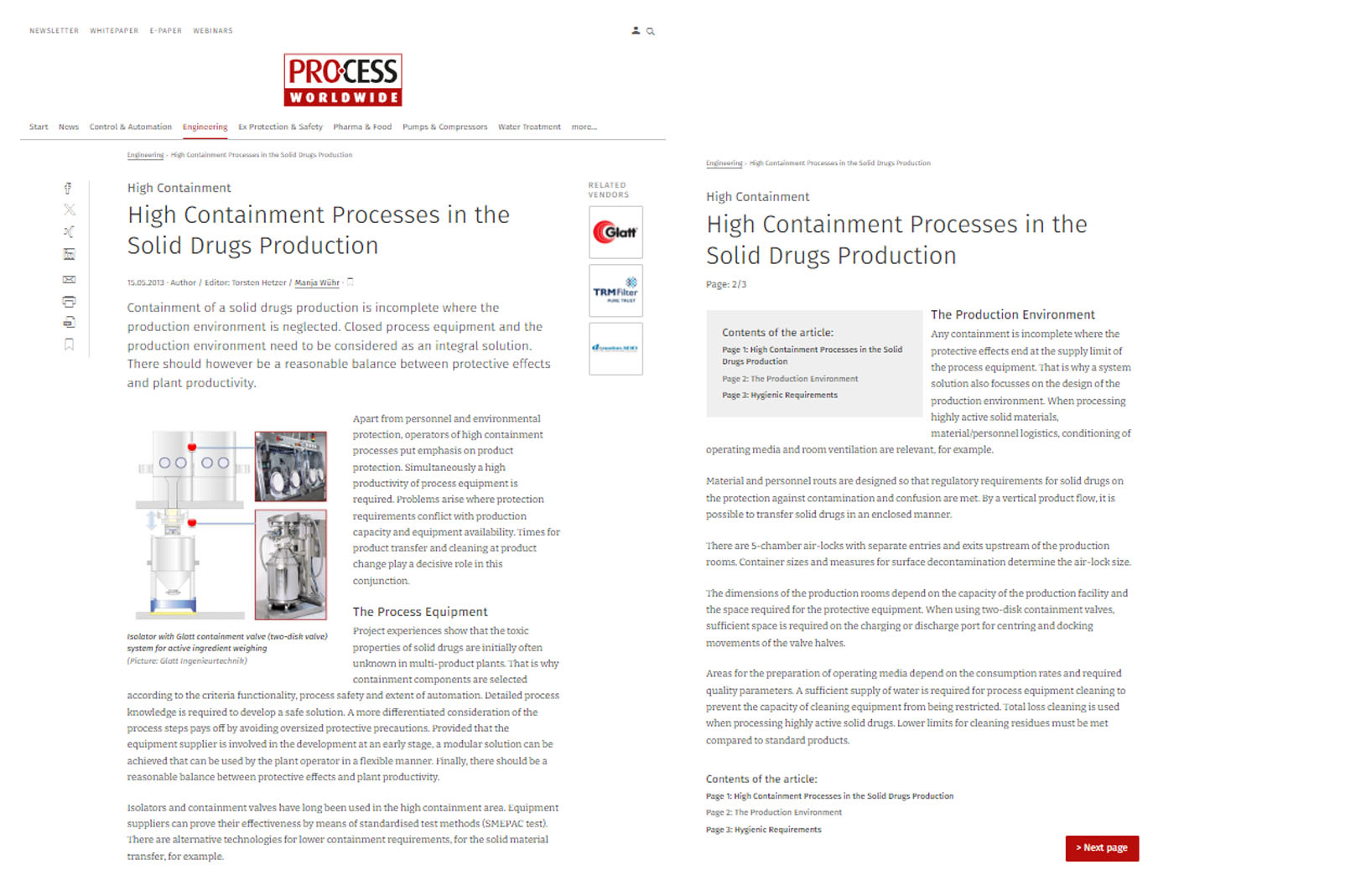

Copyright: Vogel Communications Group

Copyright: Vogel Communications GroupHigh containment for solid drugs

Copyright: Konradin-Verlag Robert Kohlhammer GmbH

Copyright: Konradin-Verlag Robert Kohlhammer GmbHProduct safety for granulation and coating – Hygienic design for fluid bed and spouted bed systems

Copyright: Wiley-VCH Verlag GmbH & Co. KGaA

Copyright: Wiley-VCH Verlag GmbH & Co. KGaAQualification of pharmaceutical plants

Copyright: publish-industry Verlag GmbH

Copyright: publish-industry Verlag GmbHLiquida processes are simply more complex

Copyright: Wiley-VCH Verlag GmbH & Co. KGaA

Copyright: Wiley-VCH Verlag GmbH & Co. KGaAInternational competence in planning – Glatt Ingenieurtechnik plans and builds complex plant lines and production facilities

Latest News

Copyright: Vogel Communications GroupCleanroom design. Doors, glazing, walls, fixturesAugust 22, 2024 - 3:14 pm

Copyright: Vogel Communications GroupCleanroom design. Doors, glazing, walls, fixturesAugust 22, 2024 - 3:14 pm Modular ATMP Production. ACHEMA 2024May 16, 2024 - 7:43 pm

Modular ATMP Production. ACHEMA 2024May 16, 2024 - 7:43 pm Modularisation of chemical API synthesis. ACHEMA 2024May 16, 2024 - 7:03 pm

Modularisation of chemical API synthesis. ACHEMA 2024May 16, 2024 - 7:03 pm Glatt Engineering with Robotics at ACHEMA 2024May 16, 2024 - 3:51 pm

Glatt Engineering with Robotics at ACHEMA 2024May 16, 2024 - 3:51 pm Glatt presentation on MODULAR PLANNING at Lounges 2024April 5, 2024 - 1:38 pm

Glatt presentation on MODULAR PLANNING at Lounges 2024April 5, 2024 - 1:38 pm

Links

Glatt Partner

Glatt Ingenieurtechnik GmbH

Nordstraße 12

99427 Weimar, Germany

Tel.: +49 -3643 47 0

Fax: +49 -3643 47 1231

info.we@glatt.com