Save the date!

Stage Talks

TECHNOPHARM FORUM

Thu, 25 September 2025

1:00 – 1:30 pm

Speaker: Anton Kopitzsch,

Lead Automation Engineering,

Glatt Process & Plant Engineering

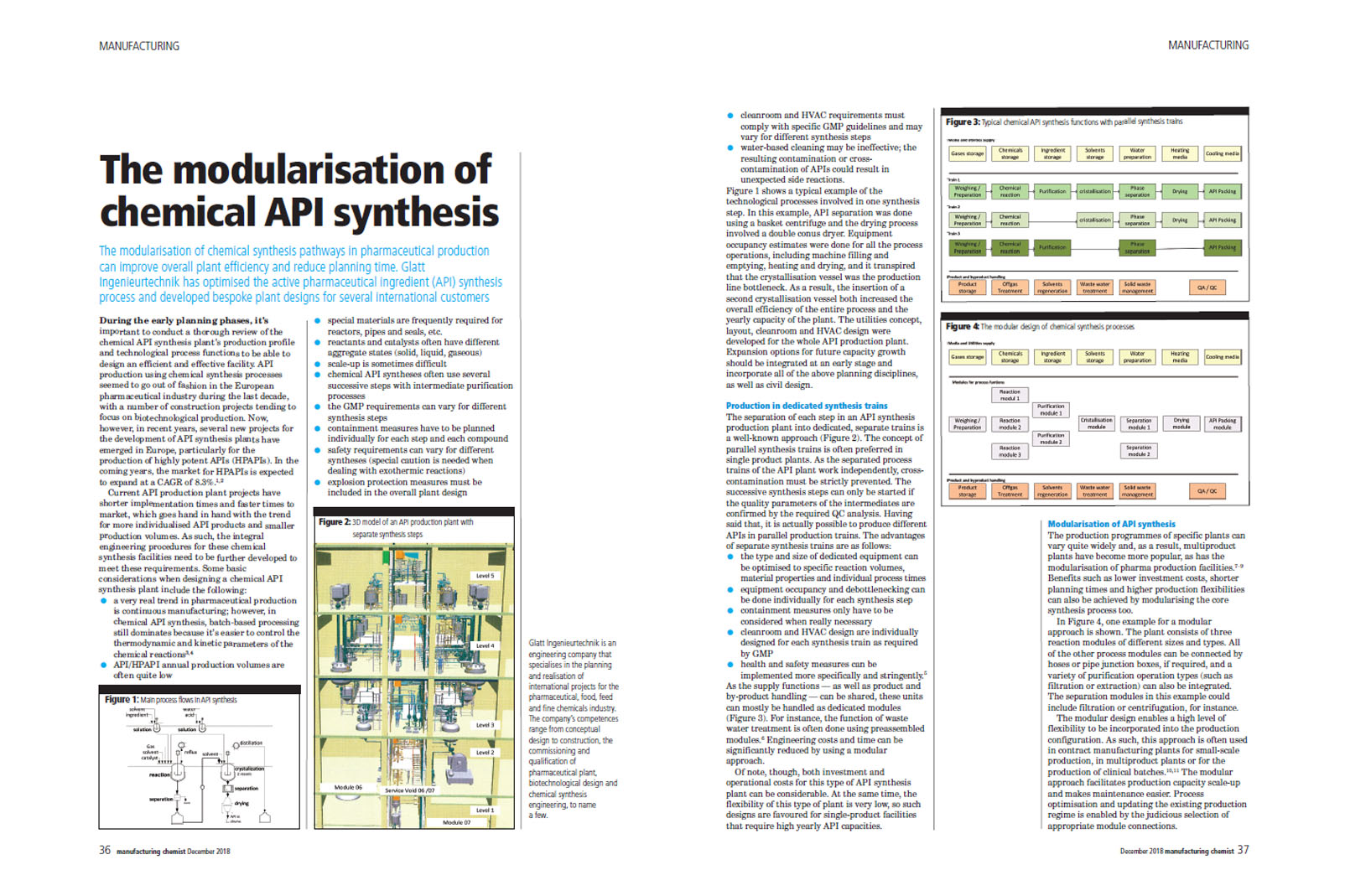

Revolutionizing Oral Solid Dosage Manufacturing:

Fully Automated Batch Execution in an Automated Production Environment

Anton Kopitzsch, Team Lead Automation Engineering, Glatt Process & Plant Engineering, will devote his session to revolutionizing the manufacture of solid oral dosage forms, outlining fully automated batch execution in an automated production environment.

An innovative approach from Glatt and Bayer integrates advanced intralogistics, tracking technology, and acquisition into a sophisticated automation system that enabling seamless operations, unmatched efficiency, and best-of-class quality control. The system offers a scalable and resource-efficient solution to meet the industry’s highest requirements and redefines pharmaceutical production.

A completely automated electronic batch record (eBR), the elimination of manual material handling using industrial robots and AGVs, as well as intelligence about all production equipment are various key elements synchronized within one ecosystem.

As part of Bayer’s SOL1 project in Leverkusen, Glatt developed the G-Connect system for connectivity at the shop floor level, which meets Bayer’s project-specific requirements. Central to this approach is the integration of the package units (PUs) to the G-Connect ecosystem, which ensures that all batch-relevant GMP data are downloaded directly to the PUs. The PUs use this information to perform all shopfloor relevant GMP-checks at the shopfloor level.

Material handling within the G-Connect ecosystem is also managed exclusively through automated communication between MES or PU and the new Glatt software. The material is – GMP-approved – automatically loaded into the process without any human intervention. The Glatt system is capable of managing equipment positions, fill levels, holding times, and all other information required for fully automated production.

A single batch encompasses the entire production chain and integrates all steps across all PUs and production units. This unified approach shifts the paradigm from viewing batches as outputs of individual units to seeing them as products of the entire shopfloor.

Quality control is achieved through 100% automated execution of the eBR and real-time monitoring of critical process parameters. In addition, the automated eBR system enables a “review by exception” process that drastically reduces the time and effort required for product release in compliance with regulations.

Glatt’s full shopfloor automation solution ensures automated documentation with real-time compliance checks, eliminates errors, and increases efficiency by automating material handling and production processes. It sets a new benchmark for pharmaceutical manufacturing and is an innovative beacon for the future.

Meet the Glatt Experts at Powtech & Technopharm 2025 at the stand 10-420!

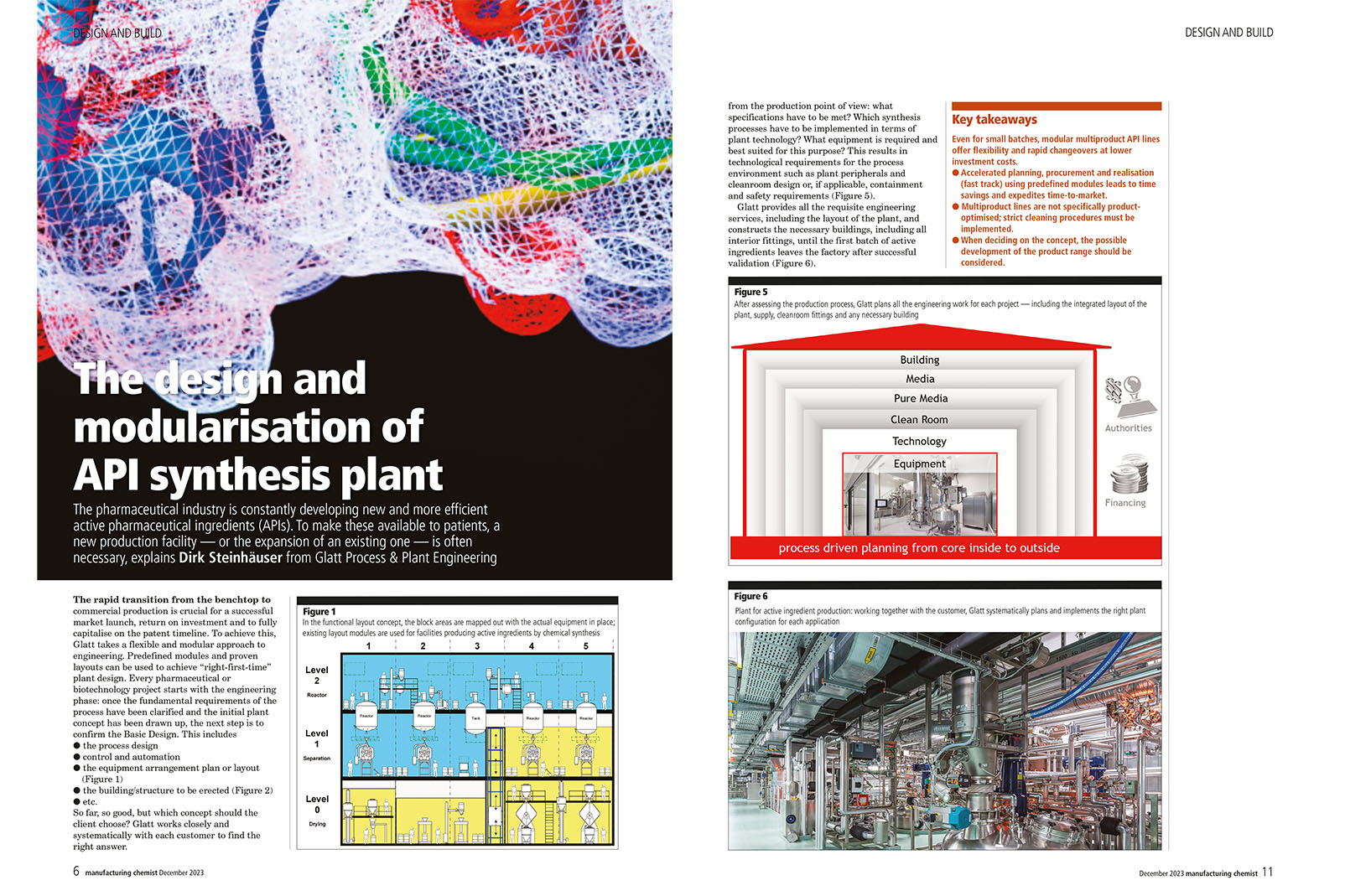

Learn more about the expertise and services of Glatt Process & Plant Engineering Pharma + Biotech from the idea to the realization of pharmaceutical or biotech production facilities.

Copyright: Bayer

Copyright: Bayer